By Aaron Foyer

VP, Orennia

This may not come as a surprise, but the Earth was quite a different place 4 billion years ago. In the geological eon known as the Archean, the planet was closer to a fiery Mordor with few signs of orcs or any other lifeforms. The atmosphere was equally perilous. The concentration of carbon dioxide was several orders of magnitude higher than what it is today. So, where did all that atmospheric carbon dioxide go?

The original carbon capture: As the Earth settled and the first mountains and water systems formed, the process of weathering and erosion brought little chips of rock and minerals down the rivers and into the oceans. At the same time, carbon dioxide from the atmosphere reacted with water to fill the oceans with bicarbonate which, when mixed with eroded rocks, formed calcium carbonate. This precipitated out of the water and fell onto the ocean floor where it accumulated and formed limestone.

Over billions of years, this process actively and permanently trapped huge volumes of carbon underground. Today, there is 10,000 times more carbon stored underground as rock than in the atmosphere, all due to the process of mineralization.

Fast forward 4 billion years: To address climate change, scientists and engineers are now looking for ways not only to capture carbon, but also to sequester and store the greenhouse gas safely and permanently. Could this billion-year-old natural mineralization system be the great solution for carbon storage?

Background

Carbon capture is now broadly accepted as a key tool for decarbonization. Carbon emissions can either be captured from point sources emitters like large industrial facilities or pulled out of the air with technologies like direct air capture (DAC). While these technologies continue to advance, dealing with the carbon dioxide once it’s captured is a whole other issue.

The options: There are many, including using it for various industrial and commercial applications and storing it inside geologic reservoirs. Each comes with its own challenges.

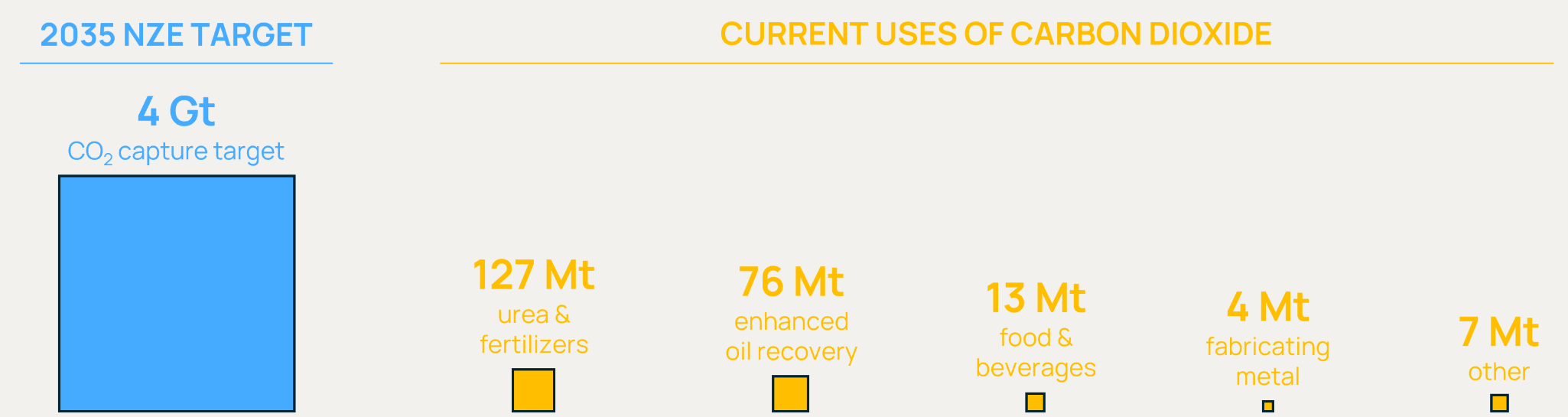

For utilization, we simply don’t have enough use cases. The International Energy Agency (IEA) estimates the world currently uses 230 megatonnes of carbon dioxide every year, most of it for urea used in fertilizers and for enhanced oil recovery. That’s a far cry from the 4 gigatonnes the IEA believes the world will need to use or store in ~10 years to achieve net-zero emissions by 2050.

Annual global carbon dioxide capture and utilization rates

Data source: International Energy Agency

To manage those volumes of carbon dioxide, either sparkling negronis are going to become very popular or sequestration will have to be unlocked at an industrial scale.

On storage: Most efforts today are focused on finding sedimentary reservoirs with enough pore space to house large volumes of carbon dioxide, but this comes with risk. While the hope is emissions stored underground stay underground forever, there are fears they could leak back to the surface, undoing all the great capture work.

Instead of being stored inside rock pores, what if carbon dioxide just becomes rock instead?

Enter mineralization

To turn carbon dioxide into rock, there are two key elements to be aware of: calcium and magnesium. These are important as they narrow the types of rocks that can be used. Technically speaking, the best-suited are those rich in minerals like serpentine, olivine, peridotite and brucite. Non-technically speaking, as a geologist co-worker put it, “it’s lava rocks.”

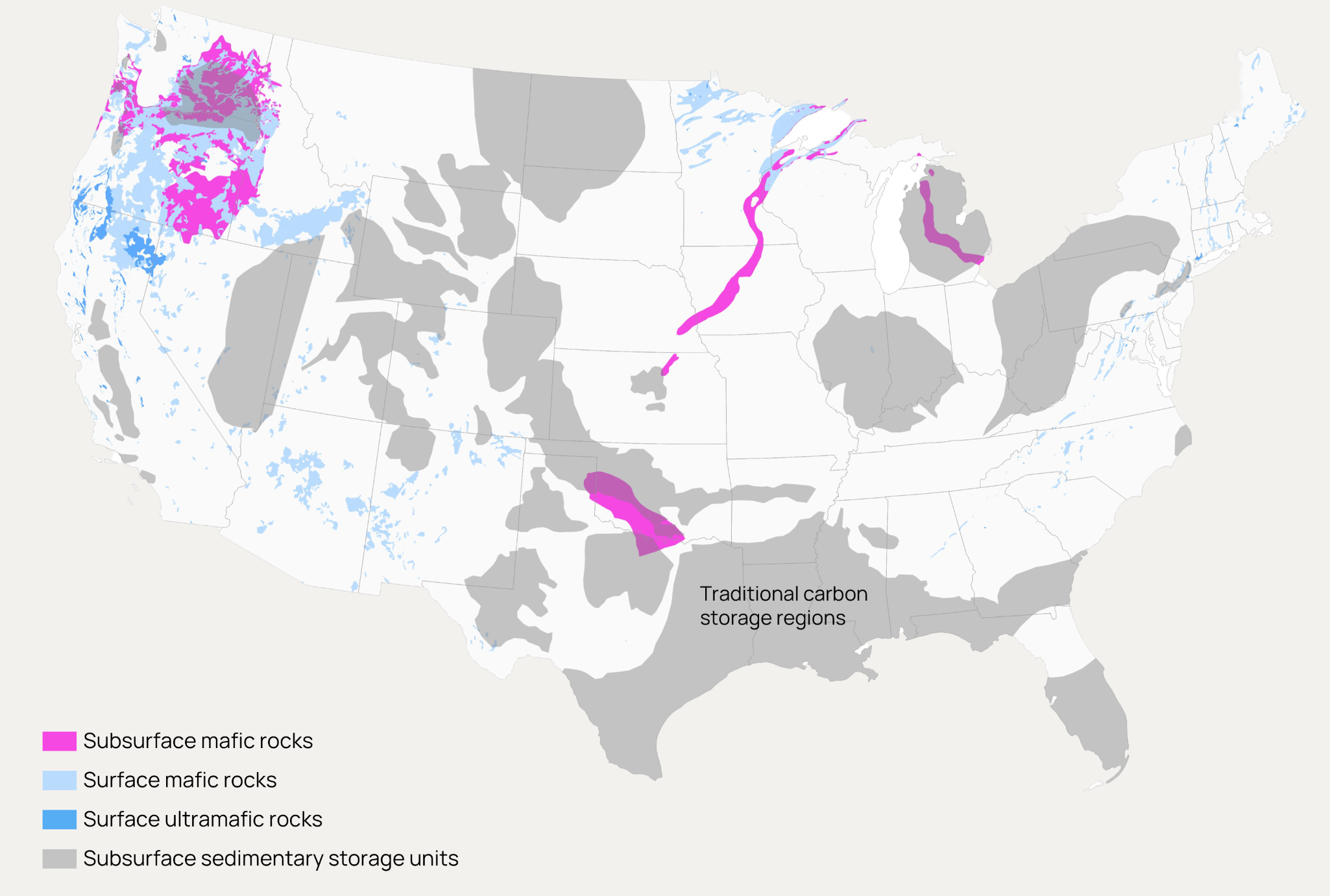

Why that’s important: First, these are not the typical reservoirs most carbon capture hubs are currently targeting, which are sedimentary. A key benefit of mineralization is it widens the carbon storage fairway, creating opportunities in new regions. Given how expensive (not to mention politically challenging) it can be to transport carbon dioxide, having additional storage regions closer to emission sources is no small benefit.

Carbon Storage Regions Across the US

Data source: The US Geological Survey (USGS)

Second, the mineralization process often takes just a couple of years And these types of rocks allow engineers to get creative on both where and how to use them.

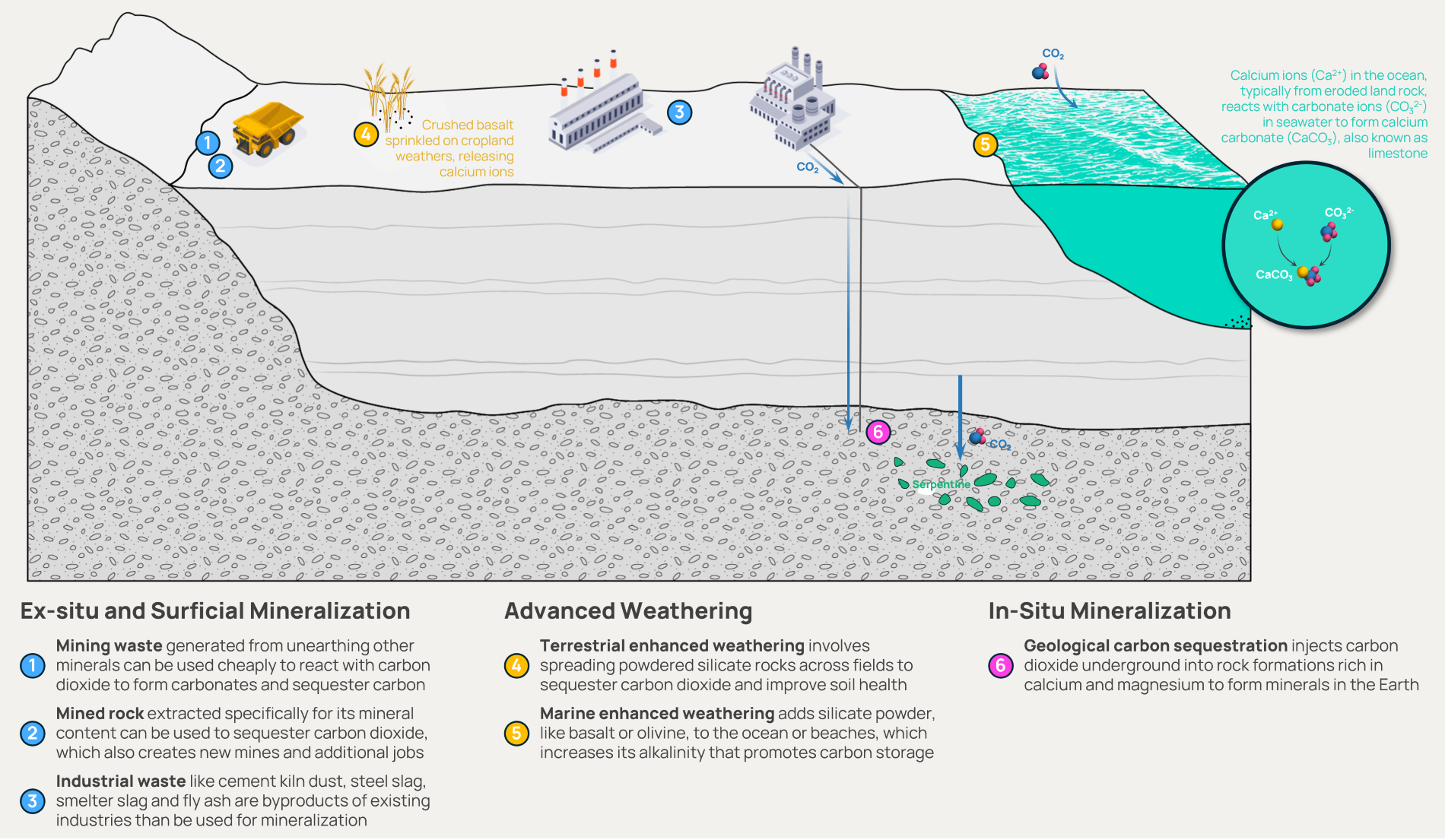

In situ: For example, like the traditional sedimentary reservoirs, carbon dioxide can be injected deep underground. The key difference being permanent storage through mineralization occurs in just a few years and is known as in-situ mineralization.

And there’s lots that can be done above ground.

Ex situ: In a set of processes known as ex-situ mineralization, the byproducts of industrial facilities and mines can be used to sequester carbon. By using the byproduct of byproducts, these are often cheap solutions.

Industrial waste like coal ash, slag from steelmaking and cement kiln dust is often rich in materials that react with carbon dioxide, meaning it can be collected and used for mineralization. Some brines produced by industries like oil and gas can also do the trick.

Being perhaps the only species that could challenge the Lord of the Rings dwarves at mining supremacy, there’s lots that we can do with the huge volumes of mining waste dug up every year, too. Several important global metals, including nickel, chromium and cobalt, are found nestled into rocks suitable for carbon mineralization.

The Different Paths to Carbon Mineralization

On a recent CIBC podcast, Paul Needham, CEO of the carbon mineralization company Arca, explained the opportunity with mining waste.

“Nickel mining, for example, a good nickel mine these days might be 1% nickel. So, if you think about that, 99% of what they mine and blast and crush and process is not nickel. All that extra material is the mine waste or the mine tailings that’s left over,” Needham said.

And advanced weathering: With enough high-quality material, ore can be ground into a mineral powder to be spread across land and drive mineralization in a process known as advanced weathering. This can include dusting crop fields, which has the added benefit of increasing soil heath, spreading along shorelines or even in waterways to prime oceans for carbon absorption.

Like any college freshman, it’s easy to fall in love with the neat rocks and fun chemistry, but let’s get to the brass tacks: what’s mineralization’s scale and how much does it cost?

How they all compare

The IEA pegs the world’s annual energy-related carbon dioxide emissions at 41 gigatons. Solutions to meaningfully remove global emissions require scale to be relevant, and a key benefit to rocks is there are a whole lot of them.

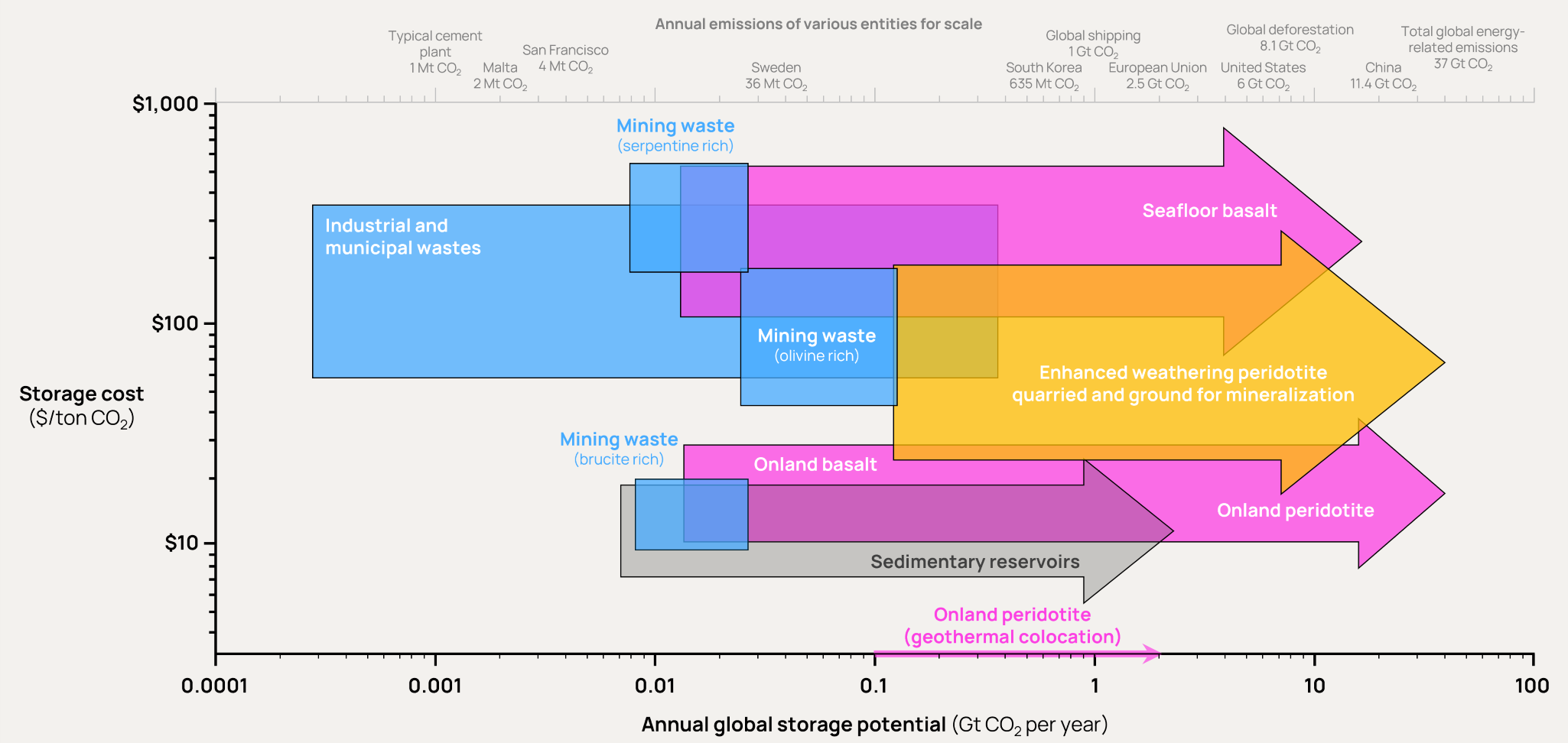

Scale: In the Lawrence Livermore National Laboratory’s Carbon Mineralization Roadmap, the Californian research center found 1 billion metric tons of carbon dioxide could be mineralized globally every year by 2035 — that 3% of global emissions. By 2050, mineralization could scale to 10 gigatons. And that’s just ex-situ mineralization using mine tailings and industrial waste. For underground mineralization, there are limited studies, but it’s generally believed to be orders of magnitude larger than aboveground. The US Geological Survey estimates the basalts of the Columbia River Valley alone could store between 10 and 100 gigatons of carbon dioxide.

Comparison of the Various Carbon Mineralization Techniques

And cost: With the caveat again that it’s still early days, the costs are not unreasonable.

The US National Academy of Sciences studied the carbon dioxide storage costs of various mineralization methods. In some cases, like land-based underground storage and some mining wastes, costs are on the order of $10 to $20 per ton. This is similar to injecting into subsurface aquifers in sedimentary reservoirs. For enhanced weathering, there is a wide range of costs, ranging from $30 to $200 per ton, with the added benefit that the carbon capture is free.

Big picture

Far from just neat chemistry and government studies, carbon mineralization projects are already starting to operate.

For projects sending carbon dioxide underground, there are a couple notable projects. In Iceland, the startup CarbFix is working with ON Power to build the world’s first near-zero emission geothermal power plant. Up to 500,000 tons of carbon dioxide will be captured from the plant and sent underground where it will mineralize in ~2 years. And in Louisiana, Heirloom Carbon is building two DAC facilities to capture up to 300,000 metric tons of carbon dioxide per year, which will then be sequestered underground to mineralize. Heirloom is one of the finalists for the $100 million XPrize.

There is no shortage of companies working on projects aboveground, either. Lithos Carbon — another XPrize finalist — is grinding up basalt to spread on cropland that will both enrich soils with micronutrients to supercharge radish growth and eventually create limestone to be stored on the ocean floor. Meanwhile, Planetary Technologies is adding antacids to the ocean, like TUMS at an industrial scale, to accelerate carbon removals at sea.

Bottom line: All these projects and technologies are looking to permanently store carbon dioxide from emissions. While orcs of Mordor emerged from the ground to cause trouble for the people of Middle Earth, mineralization can ensure the same thing doesn’t happen with carbon dioxide to our Earth.

Sparked thoughts

- Occam’s Razor? Compared to the chemical gymnastics of turning, say, wind into power, power into hydrogen, hydrogen into ammonia and ammonia back into power, accelerating geology is simple. Simplicity is a virtue, especially when it has global scale potential.

- Missing business model? A key benefit of carbon utilization projects is selling to a willing buyer. Most of the carbon mineralization projects require government subsidies or carbon dioxide removal (CDR) credits to pay them, which presents some existential industry risk if they go away.

- Except advanced weathering? Providing a soil enhancer to farmers, many of whom are struggling from high fertilizer prices, could help those willing to pay outright for basalt dusting if the price is right.

- In situ we trust? CDRs have historically faced credibility problems. In-situ projects that can roughly account for how many tonnes of carbon dioxide have been pumped underground feels more trustworthy and creditworthy than sprinkling some crushed rocks on the beach.

Aaron Foyer is Vice President, Research and Analytics at Orennia. Prior to Orennia, he leveraged his technical background in management consulting and finance roles. He has experience across the energy landscape including clean hydrogen, renewables, biofuels, oil and gas, petrochemicals and carbon capture.