Aaron Foyer

Director, Research

How sensors and the Internet of Things can address transmission issues

Aaron Foyer

Director, Research

If you happen to catch practice tapes of top European soccer (sorry, “football”) teams like Manchester City or Real Madrid, you’ll notice that players are often wearing short black vests. Far from the latest GenZ stylings, these high-tech wearables log both the location and biometric measurements of each player. This data is transmitted right to training staff, who turn athletes into virtual lab rats.

Leveraging the data: In the past, training regimes to increase athlete performance were mostly guidelines, like aggregate weight lifted or total time spent running in a workout. No longer. Best practices have been replaced by hard science. Gut feels replaced by analytics. Data lets trainers know the exact moment athletes over-exerts themselves in practice and need rest. Speed trackers cue coaches when a player is gassed and should be subbed off during a game. Unusual biometrics uncover hidden injuries that require physio. Simply put, the best sports teams now use real-time and dynamic data to maximize their performance.

Soccer superstar Cristiano Ronaldo was one of the early adopters going all-in with technology to improve performance. Working with wearables technology like WHOOP and using a recovery machine designed by NASA helped Ronaldo become one of the greatest to ever play the game.

Cristiano Ronaldo // Wikimedia Commons

Sports is far from the only industry to use real-time data to improve performance. Across the energy space, companies are incorporating real-time sensors and computing to get more out of every system, and that includes transmission lines—the long-distance runners of the energy transition.

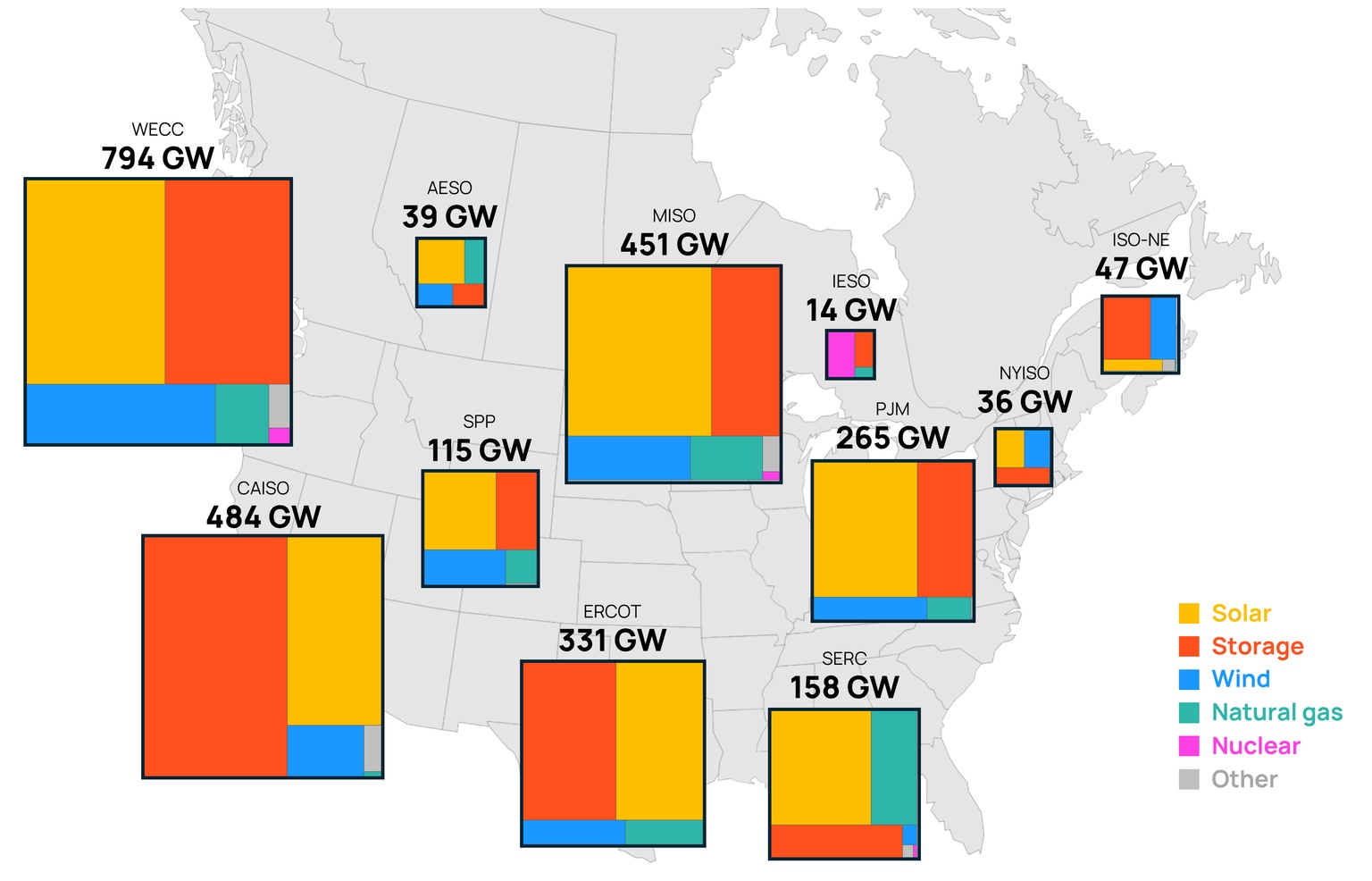

Transmission is increasingly viewed as one of the biggest bottlenecks to decarbonizing the grid, as pointed out in a note last year from Bill Gates.

“Right now, over 1,000 gigawatts worth of potential clean energy projects are waiting for approval—about the current size of the entire U.S. grid—and the primary reason for the bottleneck is the lack of transmission,” Gates said.

The obvious solution is to build more transmission lines. Easier said than done. Especially for long-distance high-voltage lines, the planning process is a little out of sync with the future needs of the grid. Once the planning stage is done, permitting remains a long, complicated process and that’s before you introduce rising NIMBYism. At best, getting adequate transmission will be slow.

Note: Includes projects with an interconnection agreement signed, in construction, inactive, in pre-study, with studies undergoing and suspended

Source: Orennia

If building out new transmission will be tough, or at least slow, can we get more out of existing lines in the meantime?

Transmission lines are surprisingly complicated when it comes to how much power is allowed to pass through them. It’s tempting to think it’s simply how much electricity a given amount of copper wire can handle before it overheats, but there’s more to it.

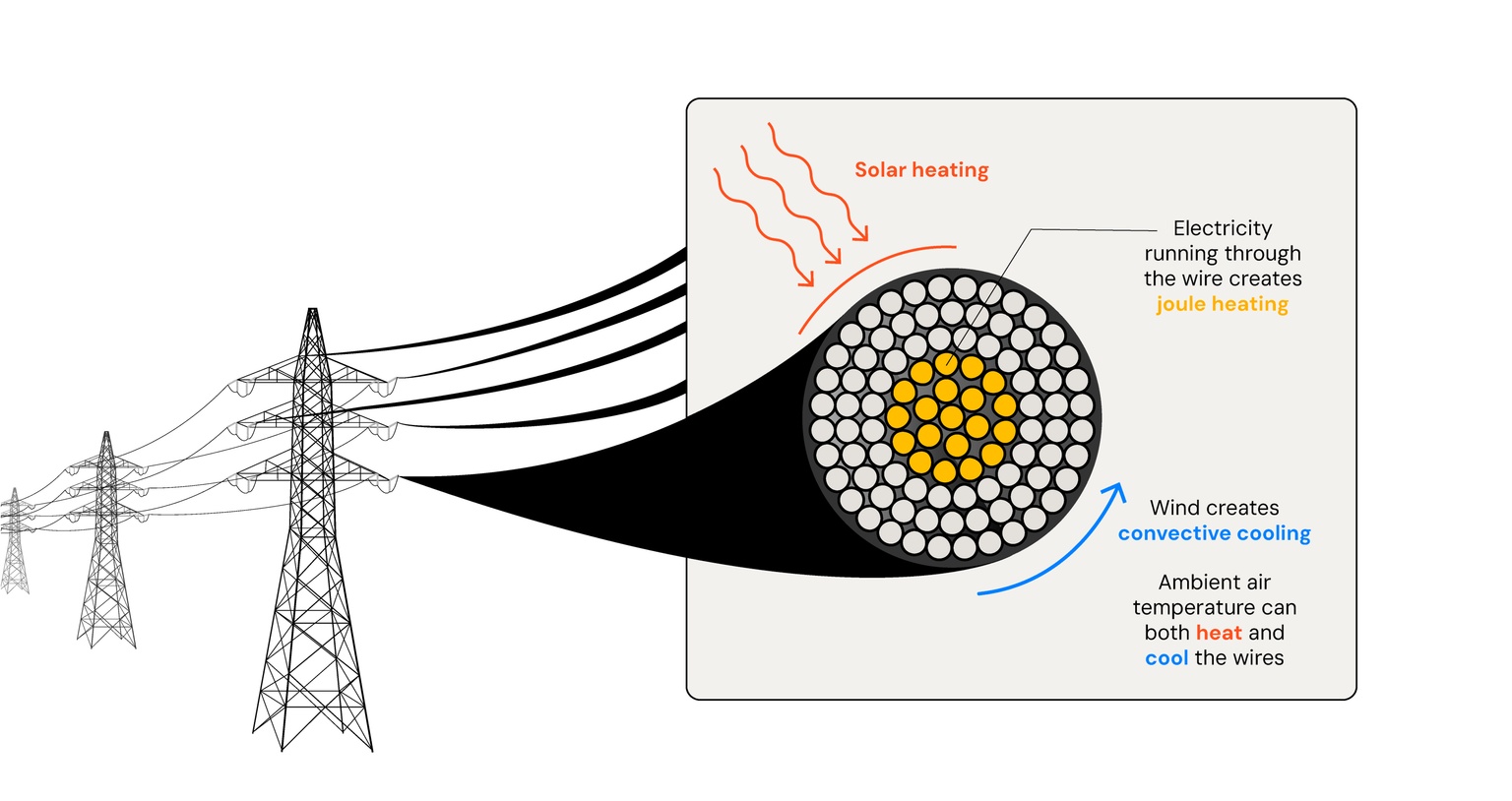

Hanging between the towers, transmission lines experience more ups and downs than Gordon Ramsay. And transmission is not so different from food, as Paul Denholm of the National Renewable Energy Laboratory (NREL) puts it: “If you blow on a hot spoonful of soup, it cools down faster. The same thing happens when the wind blows on transmission lines.”

When transmission lines are hotter, their efficiency drops. On top of this, they expand and sag with heat, increasing the risk of touching nearby trees and vegetation. By contrast, cold weather and wind cause lines to cool down and transmit more power.

Setting the limit: To avoid damaging equipment or having lines connect with nearby vegetation, operators set very cautious limits on how much voltage and amperage a line can conduct, known as its transmission line rating. These ratings are set for each line by estimating the warmest conditions they’re likely to experience over a season.

Source: Orennia

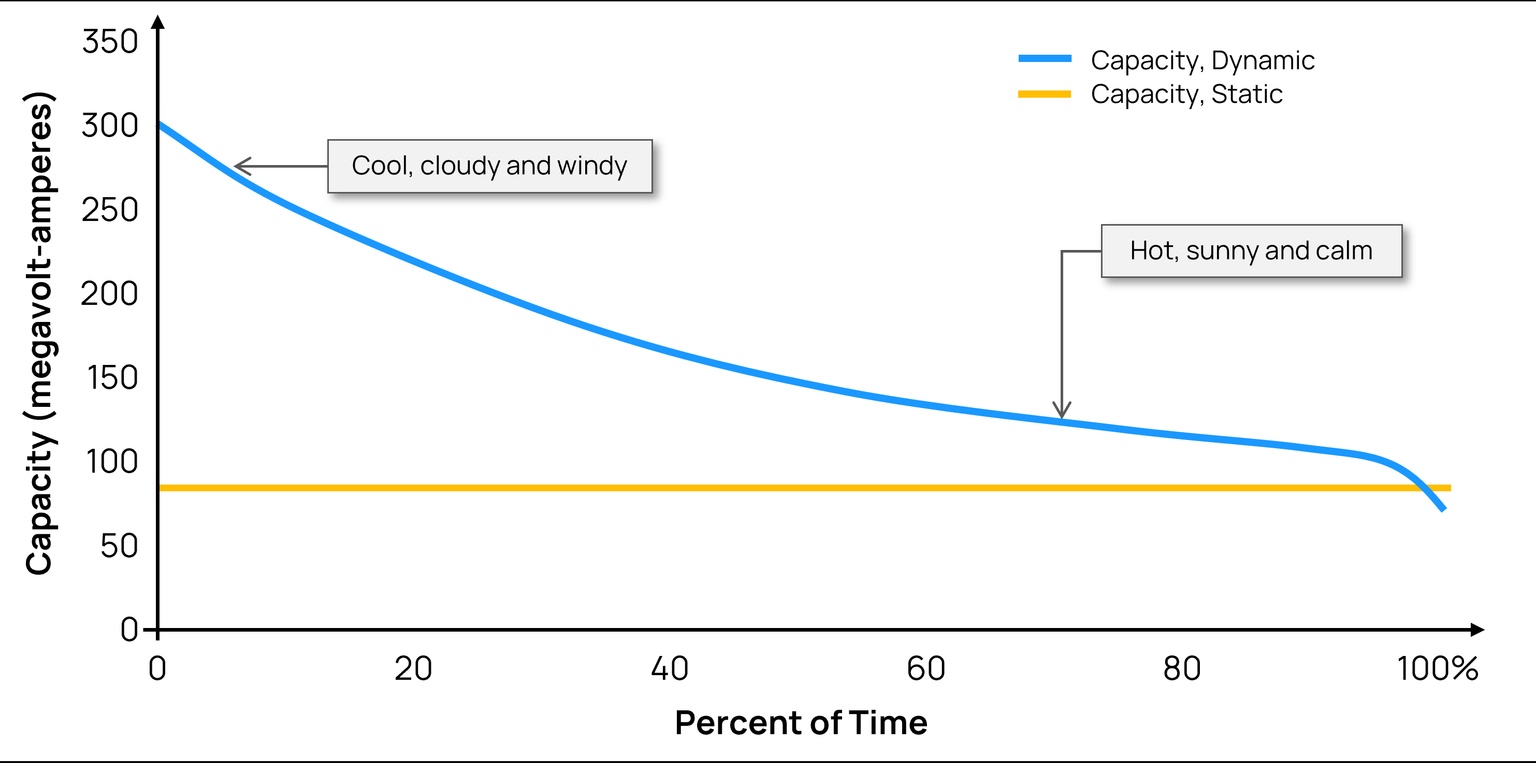

By setting line ratings conservatively, controllers avoid any situation where too much power could be sent through a given wire and cause issues. But for the vast majority of a season, transmission lines are cooler than their seasonal upper limit, so usually have transmission capacity to spare.

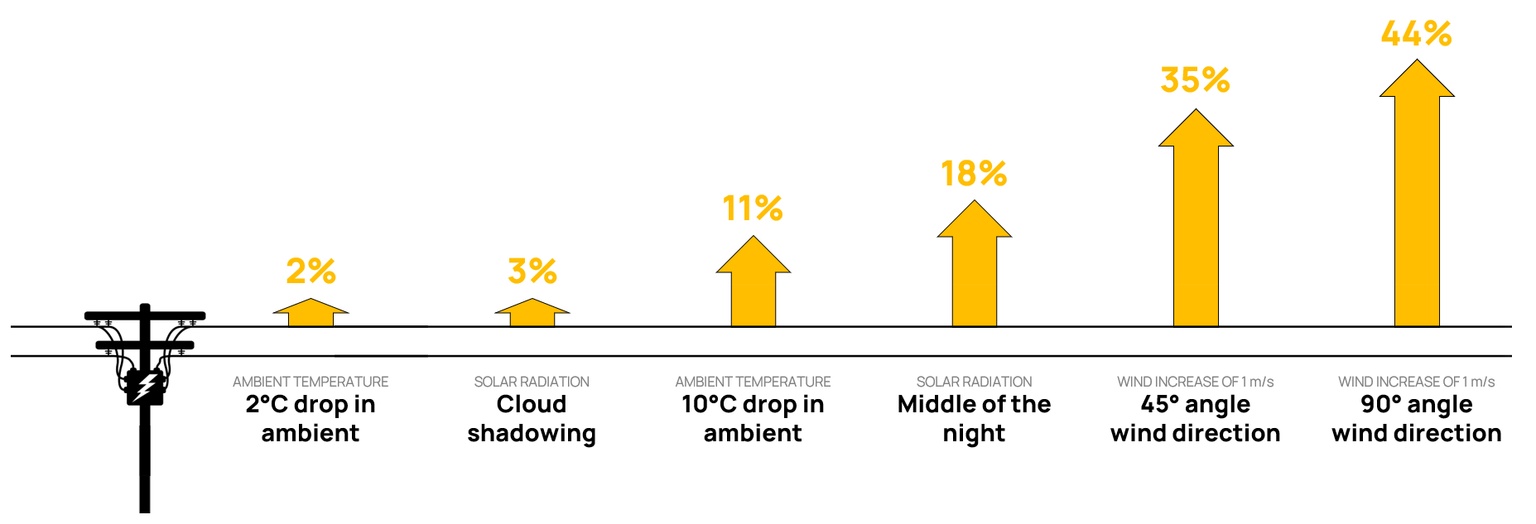

Like with athletes, a wide range of sensors and models can help improve performance. By estimating things like ambient air temperatures, wind levels and line sag, operators adjust a line’s rating up and down, depending on the conditions. This is dynamic line rating (DLR).

How to do it: There are two main approaches in setting a dynamic range:

While the direct measurements allow for more gains from power flow, both are better than simple static seasonal ratings. By leveraging information about line conditions, more power can be moved through them.

Source: Orennia; adapted from the International Renewable Energy Agency (IRENA)

There are several.

Reducing congestion: Grid congestion is a big issue and getting bigger, costing Americans $20 billion in 2022, according to estimates by Grid Strategies. Areas with abundant wind look especially well-suited to help with congestion with wind both generating electricity and cooling transmission lines. And when extreme cold weather shuts down traditional power plants, DLR can expand the grid’s capacity, enabling the use of alternative sources of power to help avoid blackouts. PJM looked at how DLR could be implemented and estimated the avoided congestion costs in just the first year of using DLR on a power line project would cover its installation costs eight times over.

Increased use of infrastructure: DLR helps amortize the cost of transmission lines over more electricity transmitted. The International Renewable Energy Agency (IRENA) summarized several studies on dynamic rating systems and found they would increase the transmission capacity by 10% to 30% for many regions. That’s good news, as the UAE-based organization sees most grid operators overcoming their operational challenges with line rating increases of just 5% to 20%.

Note: Ampacity is the maximum current a conductor can transmit without deteriorating, measured in amps

Source: Orennia, IRENA

Delaying new build costs: Under the right conditions, it’s as though additional transmission lines have appeared without building them. In the first market-integrated use in the US, PPL Electric Utilities used DLR instead of rebuilding a transmission line. It’s estimated the investment saves $60 million year-over-year and avoided $50 million for installing new wire. And it’s easier to develop DLR than build or expand existing lines, allowing for more renewables to be added in the near future.

An easy alternative: While there is a big push from Washington to get transmission built, we all know how reliable Congress is for getting stuff done these days. After the overturning of the Chevron deference, which requires more of Congress to pass more detailed bills, having tools that require less red tape to implement—like DLR—is valuable.

There are items worthy of serious consideration. On top of the initial costs to implement and added complexity in running the grids, DLR exposes the grid to risks.

A wide adoption of DLR would effectively start running meaningful parts of the grid on a huge array of sensors and IoT devices. In its report, IRENA highlighted concerns over the reliability of DLR systems during periods of extreme weather. While the fallback would be to simply operate lines at their initial conservative levels, it would mean the system could fail right when it’s needed most. On top of this, every IoT device added to the grid introduces a new point of vulnerability to cyberthreats.

Bottom line: Despite the risks, there’s no doubt line operators will increasingly install DLR systems going forward.

As Electrical Grid Monitoring CEO Amir Cohen explained in a recent interview about the opportunity for DLR in the UK, it can enable a more complex and efficient grid. In the past, the UK ran on ~100 power stations. In the future, it will be closer to 300,000 different resources—3,000 times more sources. Many transmission investments are needed to make that a reality, but DLR can help avoid many of them.

Data-driven insights delivered to your inbox.