Aaron Foyer

Vice President, Research and Analytics

Aaron Foyer

Vice President, Research and Analytics

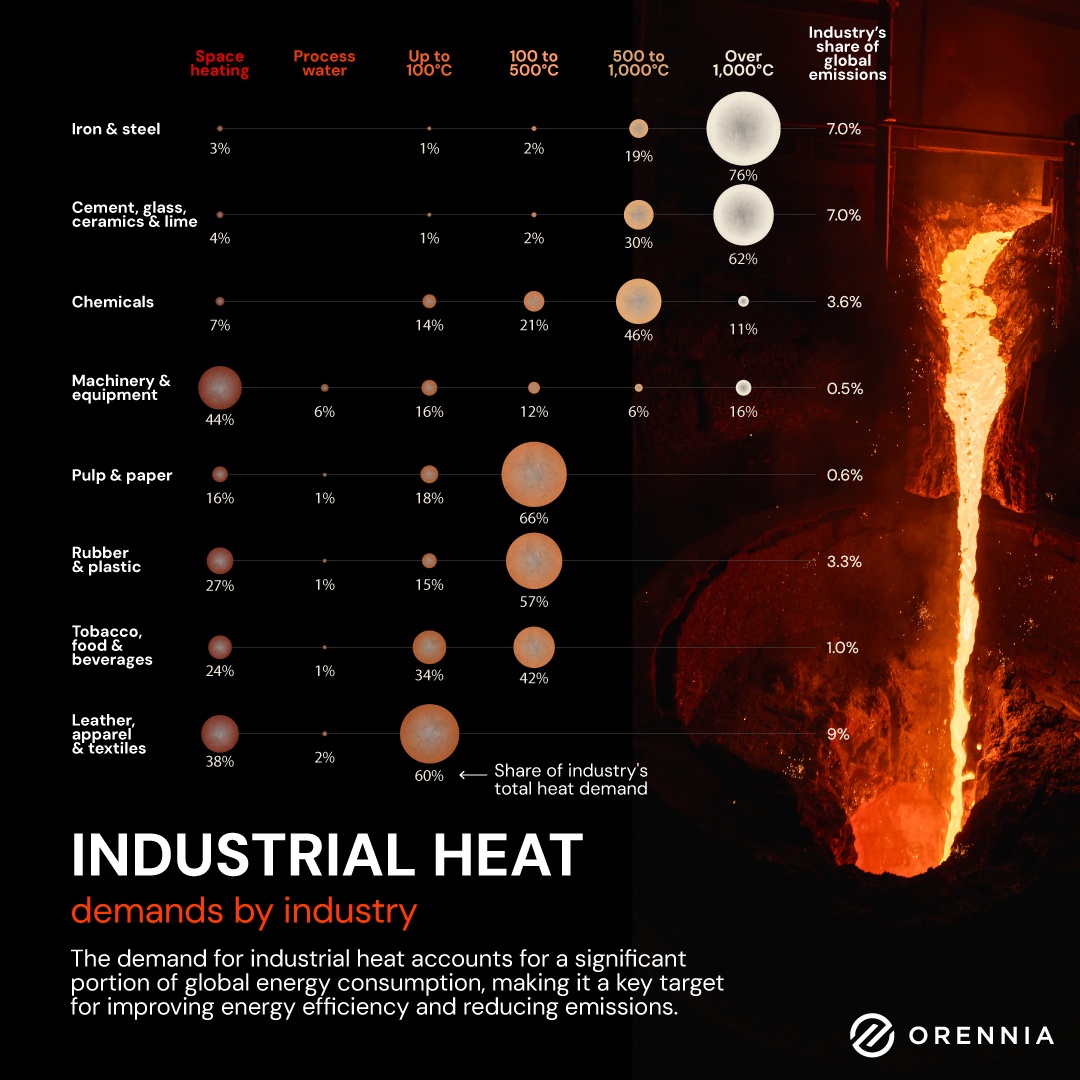

Industrial heat refers to the thermal energy needed for various industrial processes. It’s critical for manufacturing, driving everything from chemical reactions to material transformation. The heat can be used for everything from low-temperature drying to high-temperature metal forging and glass production.

Industrial heat is mostly produced through the combustion of fossil fuels, principally natural gas and coal. Electricity, biomass and renewable energy sources like solar thermal and geothermal are increasingly used to help reduce emissions. The type of heat generation required depends on specific industrial process.

Several industries rely heavily on industrial heat:

Industries like cement, iron and steel all require large amounts of hot industrial heat. Doing so creates large amounts of greenhouse gas emissions. According to the US Department of Energy, industrial heat is responsible for 9% of the entire US emissions footprint.

There are several challenges. Many industrial processes require extremely high temperatures that are difficult to achieve with renewable sources alone and fossil fuels are currently the most cost-effective and efficient way to produce the heat. Exiting industrial plants are designed around fossil fuel use–retrofitting or replacing them with renewable-based systems is expensive and logistically complex.

Renewable technologies like solar thermal and electric heating are still developing and often struggle to meet the high energy density needed for industrial processes. Achieving the same energy efficiency with alternative energy sources can be difficult, making it harder to maintain production efficiency and cost-effectiveness.

Bottom line: While the push to decarbonize industrial processes is gaining momentum, the path is fraught with technological, economic, and infrastructural challenges. Innovations in renewable energy and advancements in industrial technologies will be crucial to reducing the carbon footprint of industrial heat in the coming decades.

Data-driven insights delivered to your inbox.